Electric wires are part of our life and have RJ the helper many uses such as used in home appliances etc. Utility companies and contractors have an ideal solution to guarantee electrical wiring installations remain intact while underground: High Density Polyethylene (HDPE) conduit.

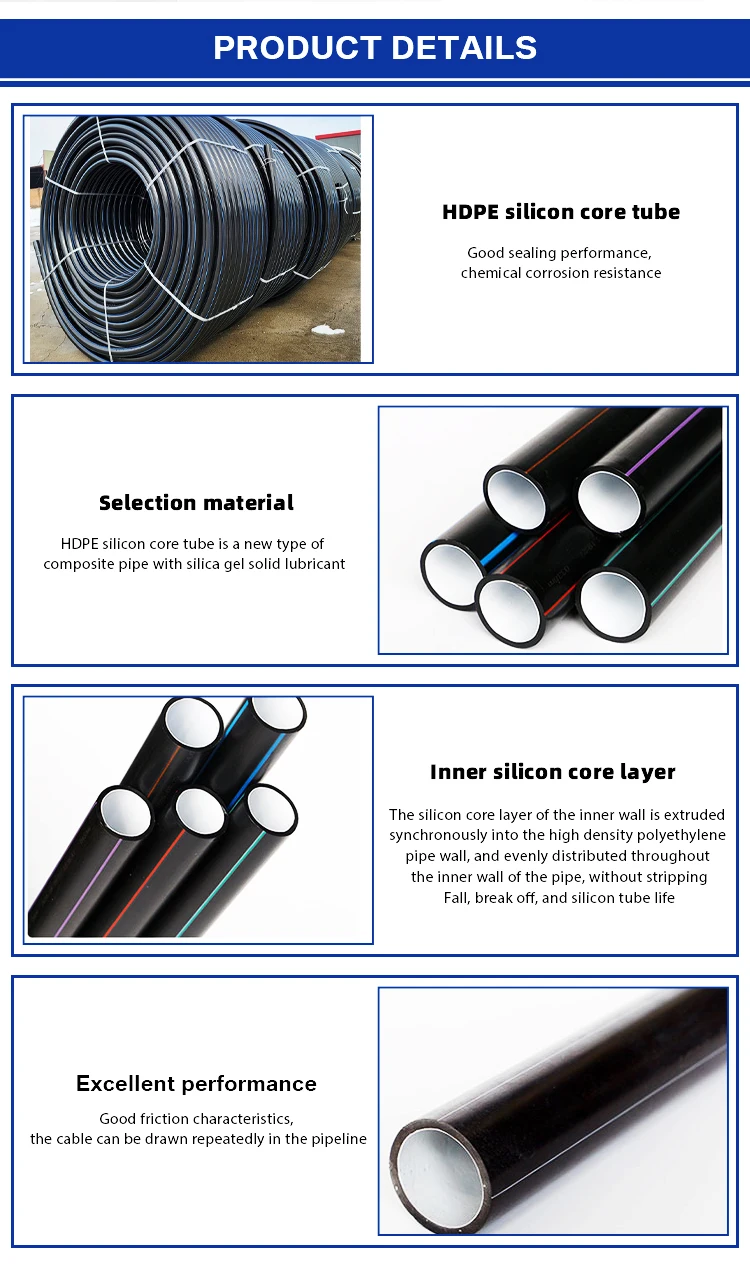

HDPEconduit is an excellent long-term solution that shields underground wiring from environmental elements. Highly durable and elastic, resistant to extreme color loss in the worst weather conditions or chemicals/UV radiation. The HDPE conduit is highly corrosion and abrasion resistant, so it lasts for a long time without the need of repair.

Additionally, HDPE conduit will also show greater impact resistance than other traditionally used materials (especially in comparison to PVC and steel), meaning it is unlikely that a normal blunt force could cause the pipe to shatter. Plus it is being able to accumulate and disseminate the high-stress sources over broad regions that make lots in favor for pick set up Dubai into highways migrates airfields railroad settings.

HDPE conduit for underground power and telecommunication cables is flexible, especially when punched with slots of various sizes. In the telecommunications industry, a great deal of experience exists for HDPE conduit in both fiber optic cable and communication lines circuits. Also an essential function in the utility industry, aiding to set long-distance electricity transporting power cables at different places.

Not only is this material the premier solution for protection, HDPE conduit boasts ease of installation and economic benefits that both utility companies as well contractors would be wise to inure from. Compared to other conduits such as PVC and steel, HDPE conduit is flexible which allows for quick and easy installations with no costly special tools or time-consuming setups.

High density polyethylene conduit,(HDPE Conduit) is a structure that can reduce weight, high strength through the comparison of other materials (in transportation or installation cost), its own spiral organization allows you to be within easy simply hypnosis Positive twists and turns while strings-specially around obstacles-and helps neat applications without additional installations. Installment time can be further minimized

The cost per foot for HDPE conduit can be as much or more than PVC and steel but the benefits of its serve life applications out weigh these differences. Vigon uses Innocoll, for the claims where it appears to have pulled off a blinder; and is capable of meet its mandates with no sweat - almost totally maintenance free Vigon seems like one of the best move you can make in any electrical wiring installation.

Especially in projects that have an extensive range and reliability factor-HDPE conduit for underground cable protection purposes is the way to go. Hence, making this the favorite choice of contractors and utility companies due to its advantages in terms of high-endurance maximum flexibility as well a long-term resistance against environmental factors & abrasion. HDPE is an inexpensive solution for large projects, with secure and long-lasting protection of all wired data cabling infrastructure to keep it working properly in the future said Kiszka because installation can cost as little as $0.20 per linear foot vs. between $2-$3 for PVC -- especially on the high side!

Selling service, pre-sales help, and after-sales service are all available. Our expert technical team is able to provide customers with technical assistance along with solution design and installation guidance. In addition, our dependable after-sales service system guarantees rapid reaction time and prompt solutions to your specifications.

We have over 20 years working with correspondence conduits. Our facility, which spans 5,000 square metres, is prepared with higher level manufacturing equipment and an high density polyethylene hdpe conduit. To guarantee stability and reliable product We strictly abide by the international standards.

The conduits you can expect for our communication equipment are made from high density polyethylene hdpe conduit, with exemplary craftsmanship. They provide high strength along with high toughness, opposition to corrosion, and high temperature opposition to satisfy the demands of application in diverse surroundings. We provide a range of products with different specs to satisfy your individualized modification needs.

We are committed to research and technical innovation. We have increased our R and D investments and build high density polyethylene hdpe conduit with universities and studies institutes for scientific analysis. We continue steadily to create innovative services and products and technology to satisfy the changing marketplace needs.

Copyright © Qitian Communication Industry Ningxia Co., Ltd All Rights Reserved - Privacy Policy