Driving Innovation in Communications: Advanced Manufacturing of Conduits and Cables

The communication industry is evolving, and newer developed technologies every time. Among the Qitian main element facets of innovation is the advanced manufacturing of and cables. We will explore the advantages of advanced manufacturing, the innovation of safety features, the application and use of these products, and how they can improve service and quality.

Advantages of Advanced Manufacturing

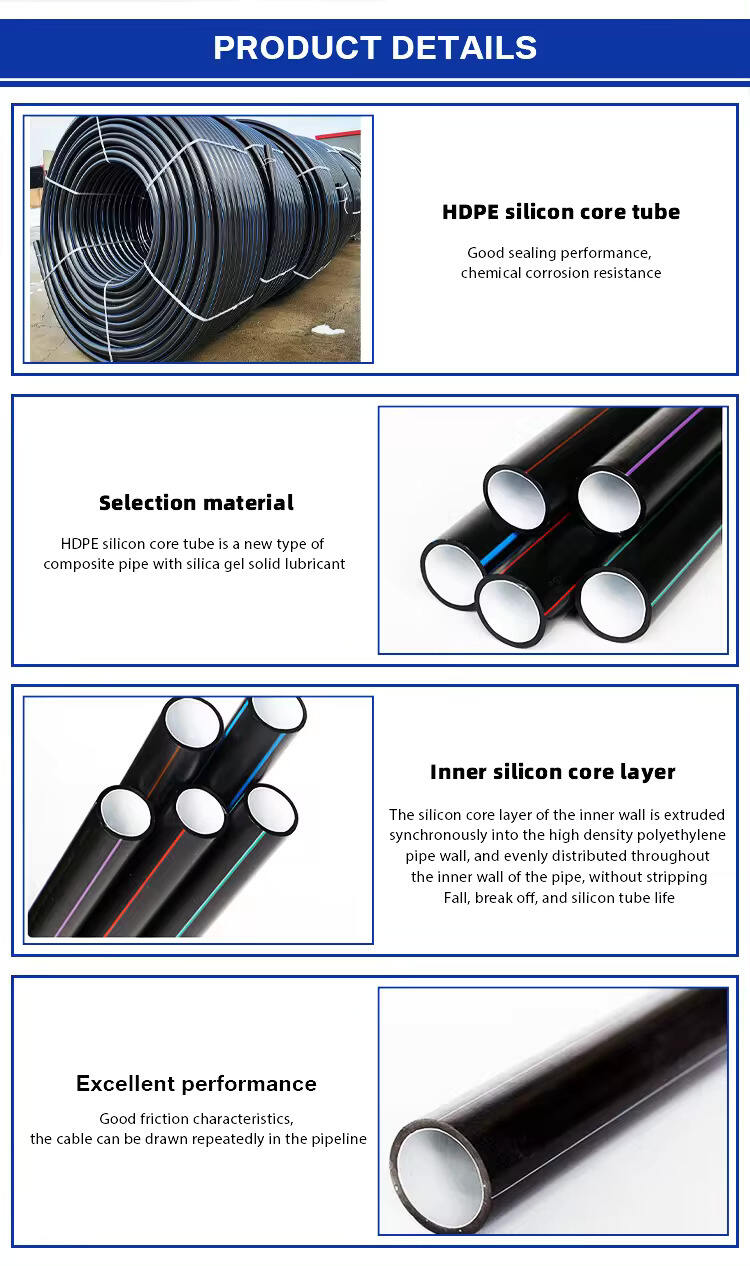

Advanced manufacturing technologies has revolutionized the communication industry, creating it feasible in order to make conduits and stronger cables, stronger, and considerably efficient than previously before. One of many biggest advantages of advanced manufacturing is their capacity to create customizable items to certain needs. Which means companies can build conduits and tailored cables to their users' requirements, resulting in best efficiency and more cost-effective solutions.

An additional benefit the use of advanced materials. These 1 core fiber optic cable materials are often lighter, stronger, and energy-efficient, which means that that they may be placed to produce products which tend to be effective and efficient than traditional materials. Finally, advanced manufacturing procedures could be more automated, that reduces the necessity of manual labor and increases effectiveness and efficiency.

Innovation in Safety Features

The safety of both employees and people is a top problem the communication industry. With advanced manufacturing strategies, safety features can directly be incorporated into conduits and cables through the manufacturing procedure. As an example, sensors allows you to identify faults or injury to the cables, alerting technicians to potential problems before they being severe, and decreasing the odds of damage or accidents.

Use and Application

Conduits and cables is utilized in a number of communication applications, including the 12mm hdpe pipe telecommunications industry, electrical energy transmission, and data centers. Advanced methods and that can be manufacturing for best efficiency and economical solutions, rendering it possible to create custom-made products for specific applications.

The use of advanced materials and manufacturing processes has lead within the developing of fiber optic cables, which are with the capacity of transmitting data faster and over longer distances than traditional copper cables as one example, in the telecommunications industry. These advantages are making fiber optic cables the chosen choice high-speed web and more digital solutions.

Service and Quality

Advanced manufacturing techniques have additionally possessed a significant effect service and quality. By producing custom-made items companies can incorporate better service making use of their customers, and with the use of advanced materials and manufacturing processes, they could boost the quality of the merchandise.

For instance, the use of advanced materials could reduce the degrees of maintenance needed for conduits and cables, causing extended service and fewer disruptions to service. Similarly, the 12mm microduct use of automated manufacturing procedures can lessen the alternative of errors, causing services and products being of higher quality and more reliable.